COURSE OBJECTIVES

This the course is designed to provide training in the application of Lean Six Sigma methodology designed to reduce wastage which appear in any who in shape at realization process, product or service. With studies case, course helps in building competence for efficient and effectively management business processes.

COURSE OUTCOMES

Participant course will be able to :

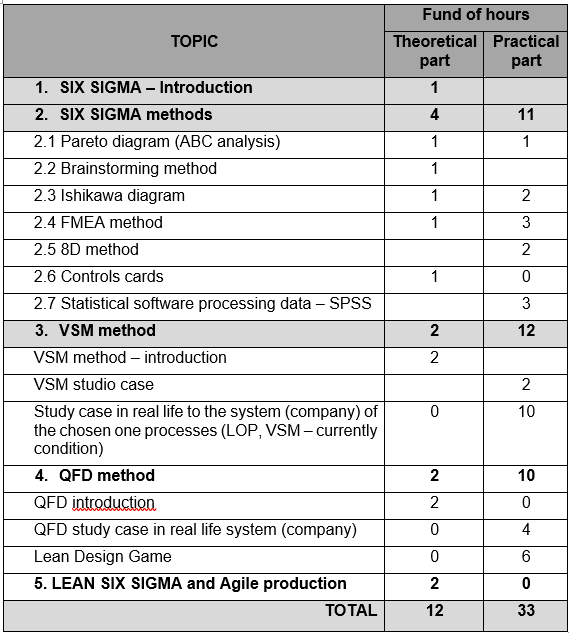

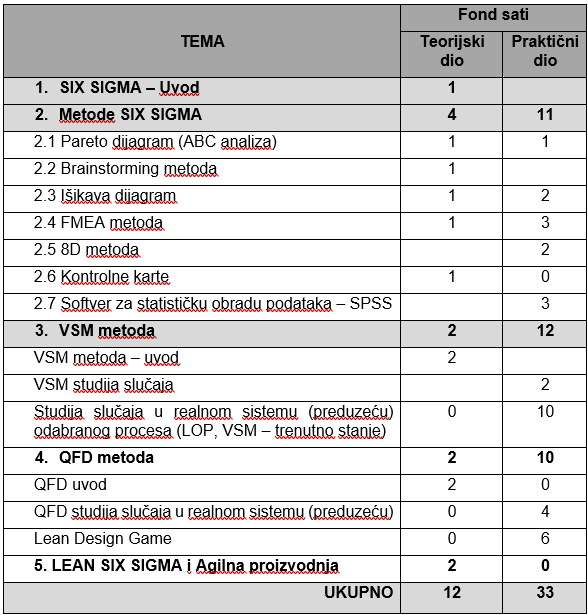

· explain Lean Six Sigma methodology and phases of the DMAIC (Define, measure, analyze, improve, control) model

· application certain statistical tools and measurement techniques and analysis performance process and reduction shortcomings and variability

· prepare map process using VSM tool (mapping flow values),

· identifies waste, narrow throats and potential areas improvements in observed processes

· benefits methods for analysis cause problems (e.g. using diagram fish bones or 5 Why) in real processes and suggest solutions to the goal prevention repetitions inconsistencies

· designs and application measures optimization improvements process in order to creation value for the customer,

· works in a team and independently leads projects improvements process.

Course realization:

Prof. Dr. Zorana Tanasić

Prof. Dr. Goran Janjić

CILJEVI KURSA

Ovaj kurs je osmišljen da pruži obuku u primjeni Lean Six Sigma metodologije dizajnirane da smanji rasipanja koja se pojavljuju u bilo kom obliku pri realizaciji procesa, proizvoda ili usluga. Uz studije slučaja, kurs pomaže u izgradnji kompetencija za efikasno i efektivno upravljanje poslovnim procesima.

ISHODI KURSA

Učesnik kursa će biti u stanju da:

– objasni Lean Six Sigma metodologiju i faze DMAIC (Definisanje, mjerenje, analiza, poboljšanje, kontrola) modela

– primjeni određene statističke alate i tehnike za merenje i analizu performansi procesa i smanjenje nedostataka i varijabilnosti

– pripremi mapu procesa pomoću alata VSM (mapiranje toka vrijednosti),

– identifikuje rasipanja, uska grla i potencijalne oblasti poboljšanja u posmatranim procesima

– koristi metode za analizu uzroka problema (npr. korišćenje dijagrama riblje kosti ili 5 Zašto) u realnim procesima i predloži rješenja u cilju sprječavanja ponavljanja neusaglašenosti

– dizajnira i primjeni mjere poboljšanja za optimizaciju procesa u cilju stvaranja vrijednosti za kupca,

– radi u timu i samostalno vodi projekte poboljšanja procesa.

Realizacija kursa:

Prof. dr. Zorana Tanasić

Prof. dr. Goran Janjić

- Mësues: Zorana Tanasic